BOTANY

Community Notices

Proposed upgrade of IXOM facility at Matraville – Now on Exhibition

About IXOM and Chlorine

IXOM currently produces chlorine at its plant in the Botany Industrial Park, which is used to manufacture several chlorine-based products used in water treatment and industrial applications. Importantly, chlorine is the main product used to disinfect water, making it safe to drink. IXOM has safely produced, stored and transported chlorine around Australia for over 100 years.

The Australian water industry needs large quantities of chlorine to ensure the health and safety of the public and the environment. The IXOM Chlorine Plant in Laverton, Victoria is currently the only plant in Australia that liquefies and packages chlorine to provide to water authorities. The disinfection of water using chlorine is essential to public health which is why water authorities and the Australian government have expressed their support for a second plant to liquefy and package chlorine in Australia.

About the existing facility

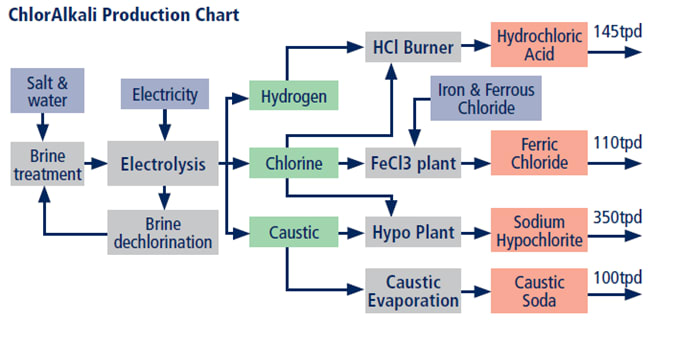

The IXOM Botany Chlor Alkali facility is an integrated complex of plants producing chlorine-based products from electrolysis of natural sea salt.

Our four main products are sodium hypochlorite, hydrochloric acid, caustic soda and ferric chloride.

The IXOM Botany Chlor Alkali facility manufactures chlorine and caustic soda from the electrolysis of salt.

Hydrogen is produced as a by-product. The plant is based on modern mercury-free membrane technology with capacity of 90 tonnes per day of chlorine.

The chlorine produced on site is used in the manufacture of hydrochloric acid, sodium hypochlorite and ferric chloride, with these downstream processes being collectively referred to as product plants. All chlorine produced at IXOM Botany Chlor Alkali facility is consumed in the product plants.

The facility at Matraville stores chlorine drums and cylinders that have been filled in Laverton, Victoria (Australia), for distribution purposes.

The following diagram provides an overview of the Botany Chlor Alkali facility and product plants process flows.

Ferrous chloride (also known as pickle liquor), recycled from steel pickling bi-products, is stored on site for use by Sydney Water in wastewater treatment and handling.

Botany Chlor Alkali Facility

The Botany Chlor Alkali facility produces chlorine and caustic soda using water, salt and electricity. Hydrogen is a by-product of this process.

The Botany Chlor Alkali facility consists of following main process areas:

- Brine Treatment/Purification

- Brine Electrolysis

- Caustic Evaporation

- Chlorine Cooling, Drying and Compression

- Hydrogen Compression

- Effluent Treatment

- Emergency Chlorine Scrubber

The Product Plants comprise of the following:

- Hydrochloric Acid Production

- Sodium Hypochlorite Production

- Ferric Chloride Production

Click here to access more information about the Product Plants at IXOM Botany Chlor Alkali facility

Proposed upgrade of IXOM facility at Matraville

IXOM are proposing to upgrade the Chlorine Plant at 16-20 Beauchamp Road, Matraville NSW to reestablish liquefaction and packaging of chlorine which occurred at the site for several decades prior to 2002.

To restart these operations, equipment in a new building will be installed on the site. This new building will also be used for the storage of chlorine containers to make the site safer.

Modification to the Chlorine Plant at the IXOM site in Matraville required an environmental assessment to be completed as part of the development application to the NSW Department of Planning, Housing and Infrastructure.

This application is now on exhibition until Tuesday 23 September 2025.

You can find the application and information about the proposal on the NSW Department of Planning, Housing and Infrastructure website here

To help people learn more about this proposed upgrade two information sessions were held in June 2025 at the Matraville RSL. IXOM team members were available to explain the proposal and answer questions.

To learn more about this proposal you can

- View our frequently asked questions here

- Get a copy of our recent notification to the community here

- Email: chlorineliquefactionproject@ixom.com

- Phone: 1800 194 718

- Register an inquiry here

Contact IXOM Botany Chlor Alkali facility

If you would like further information on IXOM Botany Chlor Alkali facility, please contact us at:

Community Complaints & Feedback: 1800 025 138

Fax: +61 2 9352 2066

Street / Postal Address:

16-20 Beauchamp Road

Matraville NSW 2036

Details of Licence Conditions

| EPA Licence No | 20547 |

| Link to full licence on the EPA website | View full licence |

| Licencee Name | Chemicals Australia Operations Pty Ltd |

| Licencee Address | 16-20 Beauchamp Road, Matraville, NSW 2036 |

Licensed Discharge Points (LDP)

The Chlor Alkali facility has three discharge points on EPA licence 20547. These are the hypo backing tower located at the sodium hypochlorite plant, the absorption tail tower located at the hydrochloric acid plant, and the emergency chlorine scrubber located at Chlor Alkali plant.

Hypo Backing Tower - LDP 1

The backing tower is the end of the line emergency scrubber for the hypo and ferric plants. Its main duty is to remove the remainder of chlorine at the outlet of the hypo plant. It is designed to scrub the chlorine to less than 1ppm even during plant upset conditions.

Tail Tower – LDP 3

The tail tower is used to dissolve any unabsorbed gases coming from the synthesis tower. By the time the gases reach atmosphere any remaining HCl fumes will have been dissolved in the demineralised water.

Emergency Chlorine Scrubber – LDP 2

The emergency chlorine scrubber is installed to remove any remaining chlorine from the gas stream before being vented to atmosphere, or if a chlorine plant process upset occurs requiring absorption of all chlorine produced. The tower absorbs the gases vented to control the pressure in the chlorine distribution system.

Emergency Chlorine Scrubber (ECS) System

The emergency chlorine scrubber (ECS) uses extraction fans to collect gas from all the chlorine-containing plant vents. The gas is then scrubbed with caustic soda to remove chlorine producing sodium hypochlorite. The reaction is as follows:

2 NaOH(aq) + Cl2 (g) → NaOCl(aq) + NaCl(aq) + H2O

The ECS is a safety critical system designed to accommodate chlorine surges during plant upsets for 10 minutes minimum of full chlorine production. All vents containing chlorine pass to the ECS system. The concentration of chlorine in the exit gas from the ECS is monitored and alarmed.

Electrical power to the circulation pumps and extraction fans is backed up by emergency power from a stand-by emergency diesel generator. A nitrogen ejector that does not require power for operation further backs up the fans. A caustic gravity head tank that does not require power for its operation, further backs up the caustic pumps.

Safety Management System

Safety management system (SMS) describes both the IXOM Corporate Safety, Health and Environmental (SH&E) Management System (SHEMS) including the SH&E Management Procedures and the facility's local safety documentation and systems, which together ensure safe operation at the Chlor Alkali facility. The facility's SMS includes how the facility implements and customises the Corporate SH&E Procedures to its particular needs, and is individual to each facility.

Basis of Safety

An additional Chlor Alkali facility operating standard is the basis of safety (BoS). The Chlor Alkali BoS provides all personnel with details of significant process hazards, the associated risks, the corresponding controls to manage those risks, and the individual’s role in the application and maintenance of those controls.

The Chlor Alkali BoS was established in 1999 and has featured the four major hazards on the Botany Chlor Alkali site:

- Chlorine

- Hydrogen

- Electricity

- Corrosives

Major Hazard Facility

IXOM's continuous operations at the Botany site have been deemed to be a Major Hazard Facility (MHF) and as such, IXOM is required to satisfy the requirements of the NSW Work Health and Safety (WHS) Regulation, 2011 - notably Chapter 9 relating to MHF - in order to be registered and thus approved to operate.

IXOM has prepared and submitted a Safety Case that forms part of the application for registration. It provides a written presentation of technical, management and operational information about the hazards and risks that may lead to a major accident and the control of these hazards and risks.

IXOM’s implemented Safety, Health and Environmental (SH&E) Management System, processes, procedures and practices that have been developed are fit for purpose and verified by audits. The control measures adopted for the major incident scenarios are appropriate for controlling the hazards and for maintaining the risk of major incidents so far as reasonably practicable (SFAARP).

Emergency Response

Emergency Plan

Comprehensive emergency response plans (ERP) have been developed for the facility to limit the consequences and assist in managing an emergency situation which may develop at the site and have the potential to impact either onsite or offsite personnel, property or environment.

Click here to access IXOM Botany Chlor Alkali facility - Pollution Incident Response Management Plan

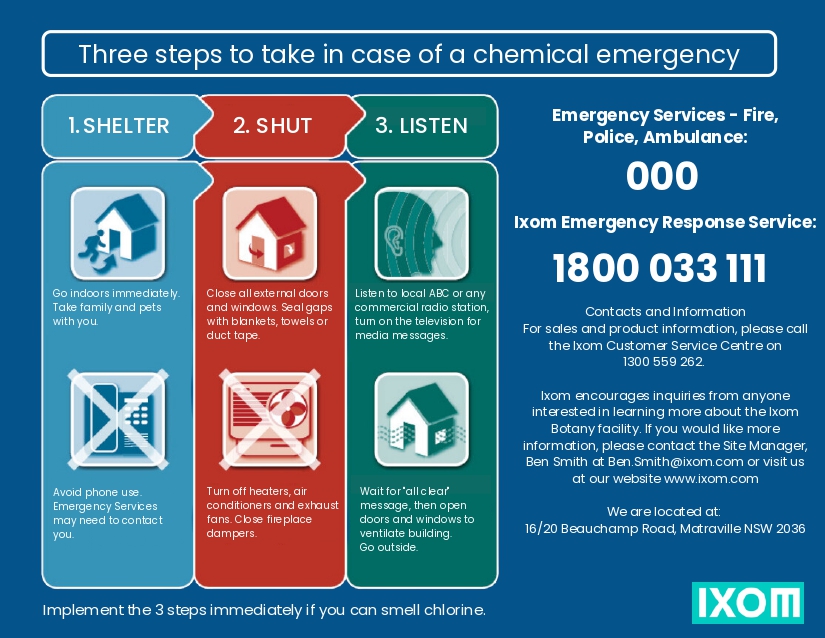

IXOM Botany Chlor Alkali facility - Emergency Steps

Emergency Trip System

The IXOM Botany Chlor Alkali facility employs a number of automated protection systems which provide multiple layers of protection to prevent hazardous scenarios from arising. Design and operation of these protective systems is dictated by numerous rigorous and systematic risk analysis and risk management practices.

Automated protective systems at the IXOM Botany Chlor Alkali facility include:

- Distributed control system (DCS)

- Hard wired instrument protective systems

- Safety instrumented systems (SIS)

The DCS is responsible for control of the production facility. Every step of the production process is monitored and controlled by the DCS. At the onset of any process upset, alarms immediately alert the operations team at which point corrective actions are taken. In the event of upsets moving the process outside of the normal operational envelope the DCS acts as the first layer of protection taking predefined control, trip and interlock actions appropriate to the situation, all of which bring the process to a safe state.

Hard wired instrument protection systems act as an additional layer of protection. These hardwired systems independently detect and respond to upsets in a similar manner to the DCS, with predefined trip and interlock actions appropriate to the situation.

Additional layers of protection are provided by the safety instrumented system (SIS). The SIS is a purpose built high integrity safety system, meeting stringent design and operation requirements.

The SIS operates independently of all other systems and responds to conditions outside of the normal operational envelope through taking trip and interlock actions which bring the process to a safe state.

The use of multiple systems and the multiple layers of protection provided by such systems is core to the IXOM Botany Chlor Alkali facility risk reduction strategy, protecting the safety of our personnel, the community and the environment.

What Could Affect the Community?

Pollution Notification

In accordance with Part 5.7A of the Protection of the Environment Operations Act 1997, IXOM Botany has prepared Pollution Incident Response Management Plans (PIRMPs).

The PIRMPs outline the processes to prevent and minimise the risk of pollution incidents and ensure comprehensive and timely information is provided to relevant authorities and stakeholders.

In the event of a pollution incident, IXOM Botany will implement the following procedure for notifying relevant authorities and other stakeholders.

The following information shall be recorded where possible and provided to those agencies requiring notification:

- The time, date, nature, duration and location of the pollution incident;

- The location of the place where hazard / pollution is occurring or is likely to occur;

- The nature, the estimated quantity or volume and the concentration of any hazards / pollutants involved;

- The circumstances in which the pollution incident occurred (including the cause of the incident, if known); and

- The action taken or proposed to be taken to deal with the pollution incident and any resulting risks / pollution or threatened risks / pollution.

Immediately contact the following authorities:

- 000 - if the incident presents an immediate threat to human health or property

- 1300 729 579 - if the pollution incident is NOT an emergency.

Emergency Services (Fire & Rescue, the police and NSW Ambulance Service) are the first responders responsible for controlling and containing incidents.

If the incident does not require Emergency Services (or once 000 has been called) notify the relevant authorities in the following order:

- EPA: 131 555

- Ministry of Health - South Eastern Sydney Public Health Unit

- Office hours: 02 9382 8233 / 02 9382 8333

- Outside office hours (request public health officer): 02 9382 2222

- 24hr incident reporting line: 1300 066 055

- WorkCover Authority: 131 050

- City of Botany Bay Council: 02 9366 3666 / 02 9366 3659 / 02 9366 3596

- Fire & Rescue (if not contacted already): 000

- If the pollution is NOT an emergency: 1300 729 579

- Department of Planning and Infrastructure: 02 9228 6413

- Randwick City Council (as required): 02 9939 0999 / 02 9937 2450 (after hours)

- The local authority of any other area potentially affected by the incident (via phone)

Following the above reporting, communication with the following groups shall occur as soon as practical to notify of a pollution incident:

Potentially affected community members (this includes owners/occupiers of industrial, commercial and residential properties) via door knocks or letter box drops. Door knocks and letterbox drops will also be used to provide early warnings and regular updates to owners/occupiers as required. Potentially affected community members will be determined based on the nature / scale of the pollution incident and the current weather conditions. Community notifications will include where possible:

- A brief statement on the nature and timing of the pollution incident;

- The party / parties responsible for responding (e.g. Emergency Services or EPA);

- The action (if any) required by the recipient of the notification; and

- Contact details for seeking further information.

NOTE: if the pollution incident presents an immediate threat to human health or property then public notifications will be made by Emergency Services.

Interested stakeholders, as appropriate for the nature / scale of the pollution incident, such as the Community Participation and Review Committee, Community Liaison Committee and the Botany Industrial Park Community Consultative Committee via phone and / or email.

An initial notification may be followed by an update (to the original recipients, or a smaller or larger group as deemed relevant) in the event that IXOM:

- is instructed by the authorities to do so;

- determines that a new or different response is required by relevant authorities and other stakeholders in response to the pollution incident; or

- decides to provide an update on the status of the investigation.

Notification may also be provided to the wider community by way of media release on www.ixom.com.

Annual Environment Reports

Click here to access the DPE Annual Reports